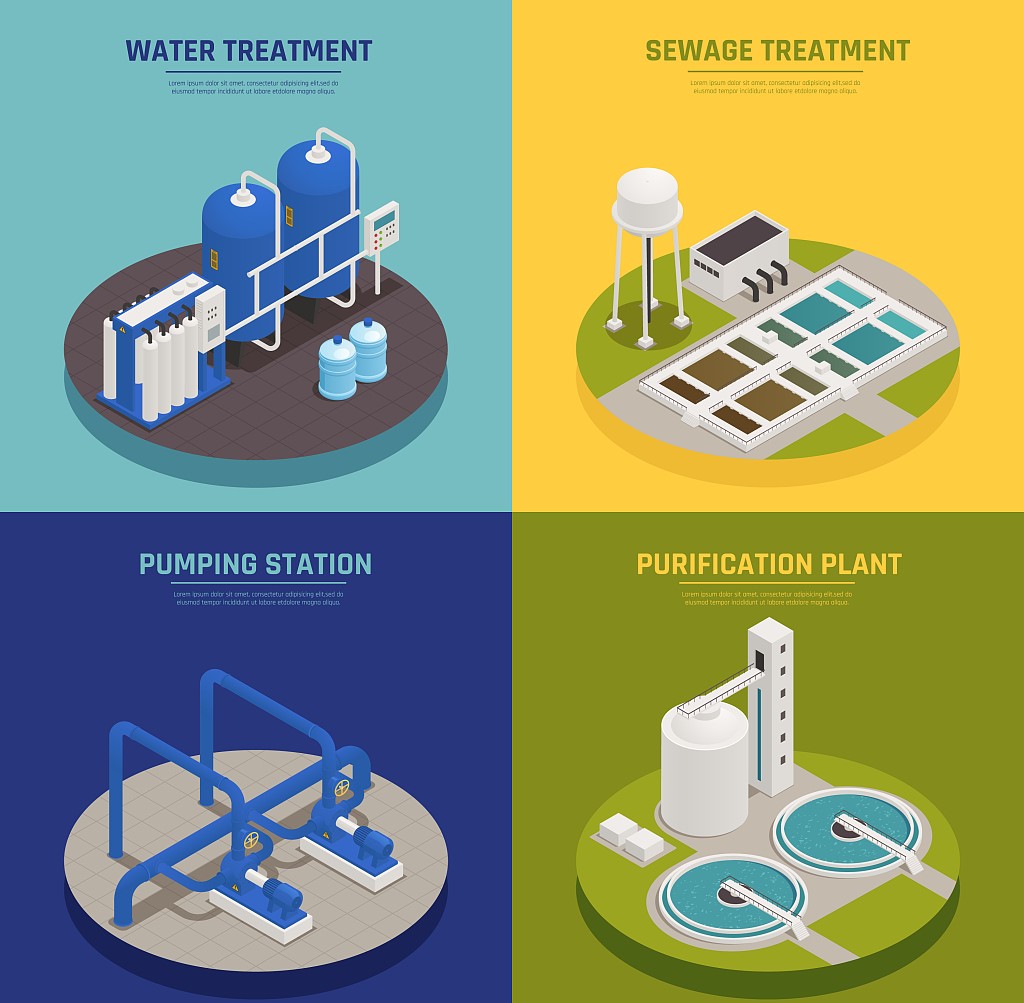

U1 is a worldwide leading company in water & exhaust-gas treatment. Head office and factories are located in the city of Changsha, Hunan province, while we've got branches all over the country as well as agents and distributors all over the world.

U1 always been adhering to the fate of continuously creating values for customers, and is committed of becoming a World-Class solution provider for waste treatment and recycling.

U1 provides design, engineering, supply and installation of environmental projects. The company possesses complete sets of process design, equipment supply, constructions, and technology innovation. We have various experiences in water & exhaust-gas treatment, industrial & domestic. After years of research, development and testing, U1 Technology has developed the Incline Bar Screen & the Multi Disk Screw Press for sludge treatment. Skid Mounted Biogas Scrubber & Ceramic Fiber Filter and the mobile treatment types with independent intellectual property rights. A series of overall solutions for the waste treatment are protected, currently with 18 invention patents and more than 33 utility model patents.

OUR ADVANTAGE

-

![]()

Machinery, as the founder of China's bedding machinery industry, is responsible for taking the lead in drafting and formulating four national standards for mattress machinery products, all of which have been passed and issued for implementation. Machinery continuously promotes research and development innovation, and currently has 10 invention patents, 20 design patents, and 28 utility model patents.

Since 2017, Machinery has transformed the mechanical production workshop with the goal of digital management, introduced high-precision terminal equipment, deployed data exchange system and terminal equipment, implemented effective management combined with MES, and organically integrated equipment, tools, instructions, processes, and personnel. Finally, the precise management of the mechanical production process and the comprehensive management of the kanban graphics have been completed, and the transformation of production scheduling from passive command to real-time active command, and the transformation of production system operation to a transparent, digital and intelligent mode. Quality control is transformed from post event statistical analysis to online monitoring.

-

![]()

Machinery, as the founder of China's bedding machinery industry, is responsible for taking the lead in drafting and formulating four national standards for mattress machinery products, all of which have been passed and issued for implementation. Machinery continuously promotes research and development innovation, and currently has 10 invention patents, 20 design patents, and 28 utility model patents.

Since 2017, Machinery has transformed the mechanical production workshop with the goal of digital management, introduced high-precision terminal equipment, deployed data exchange system and terminal equipment, implemented effective management combined with MES, and organically integrated equipment, tools, instructions, processes, and personnel. Finally, the precise management of the mechanical production process and the comprehensive management of the kanban graphics have been completed, and the transformation of production scheduling from passive command to real-time active command, and the transformation of production system operation to a transparent, digital and intelligent mode. Quality control is transformed from post event statistical analysis to online monitoring.